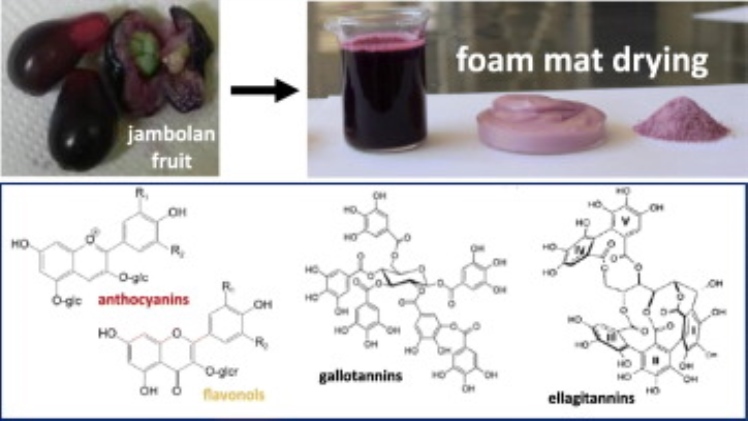

Foam- mat drying is a promising new development in the field of drying aqueous foods. This method offers a wide scope for application in vegetable puree and fruit juice processing industry as it enables the dehydration of heat sensitive foods or which are difficult-to-dry, sticky, and viscous under relatively mild conditions without undue quality change.

This technology is finding an increasing application and importance on commercial scale mostly in the drying of liquids that tender a high quality concentrate such as milk, fruit, juices, soluble coffee, etc. The foam-mat drying is a process in which the transformation of products from liquid to stable foam follows air drying at relatively low temperatures to form a thin porous honey-comb sheet or mat which is disintegrated to yield a free-flowing powder.

The dried product obtained from foam-mat drying is of better quality, porous and can be easily reconstituted. Concentration of the material prior to conversion into stable foam may or may not be an essential requirement and will depend on surface tension and consistency of the product. In spite of the fact that a large volume of gas present in the foamed mass impedes the higher rate of heat transfer, drying rate is comparatively high because of enormous increase in liquid-gas interface.

The advantages of the foam-mat drying process include relatively fast drying, easy reconstitution and better quality product. The renewed process is of potential interest in foam-mat drying for developed and developing countries for its simplicity, rapid drying at lower temperature, suitable for all type of juices, retention of nutritional quality and cost effective for producing easily reconsitituble juice powders.

History

In 1950 Eddy reported that process of production of free flowing powders of fruits and vegetables by spray drying or drum drying is facing great difficulties. To overcome these problems he recommended the use of methylcellulose for the preparation of spray dried grapefruit and orange juice powders.

Download movies from uwatchfree very easily.

Conclusion

Foam mat drying originally was developed by Morgan et al. in 1959 at the Western Regional Research Laboratory of the U.S. Department of Agriculture. The foam-mat process involves drying thin layers of foamed material in heated un-dehumidified air at atmospheric pressure and is reported to be considerably cheaper than vacuum, freeze and spray drying methods.

Read More About: [pii_email_e7ab94772079efbbcb25]