CNC is a general term that describes a general subtractive process that removes a piece of cloth or other raw material from stock and converts it into valuable products. CNC machining manufacturers are continuously designing machines to elaborate the scope of CNC machines to every field of life. This CNC machining is very useful over other machines in reduction of cycle time, greater efficiency, and much better productivity in no time.

CNC is a simple gadget, and different processes are possible in this machine to complete automatically, including milling, grinding, turning, and many more.

Types of CNC machines

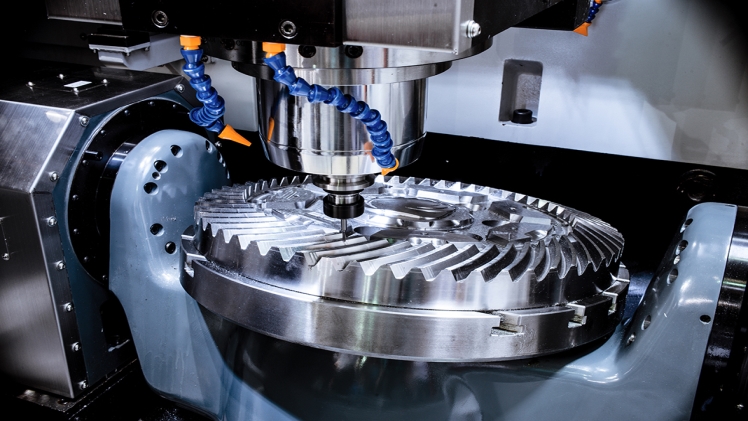

1. Milling machines

Milling machines are the type of CNC machining where the material that has to be cut is kept stationary, and its cutting is done by rotating cutting tools. This machine uses this machine to manufacture cavities, threads in the surface or produce flat surface geometries.

This method is superior to others as it is quick and obtained with very little wastage. This method has the shortcoming that it includes the usage of different tools that can cause high costs.

2. Lathes and turning machines

This method involves the rotating of raw material over rotating machines that are fixed for linear motion. Cutting of materials is done until the final material with the required diameter is obtained. This type of CNC machining is used to make tools from inside and outside like bolts, screws, andnuts.

This method is prevalent for those who don’t want to compromise on size and precision at the same time.

3. CNC electric discharge machine

If one wants to convert randomly shaped material into some fine geometric shape, one can supply electric sparks in this EDM. The given material is melted while keeping on a stand, which is then transferred into a mold that gives this material the desired shape.

This machine is commonly used for the production of machines parts that are very small or offer some difficulty in manufacturing while using other machines.

If You Need More Information Visit: magnewsworld

4. CNC plasma cutting machine

Plasma cutting is done similar to a welding wire that transfers its rays to cutting materials. The spark and intensity of plasma are all controlled through the computer using some codes. This spark will melt the material, and one can transfer it to any shape.

The material used in plasma cutting is specific; one can use only electrical conductor materials like steel and stainless steel in CNC machining.

Services offered by China CNC manufacturers

To compete with several competitors, everyone is looking for a partner that can do his job in a much better way. China CNC manufacturers provide improved efficiency with a greater yield to their users by equalizing items’ demand and supply rate.

Quality control is done three times during the production of specific material. Inspection begins from the loading of raw material, then process inspection, and finally, complete product inspection is done for better reliability.

CNC machining limitless services

Services offered by CNC machining are limitless, and one can produce desired product on his given material. Multi-axis and simple axis cutting are available for primary and complex part cuttings.

Read More About: newszone787