A number of advocates of light-duty vehicle applications for fuel cells believe that fuel cell vehicles can eventually have Lifecycle costs that are fully competitive with gasoline-fueled vehicles. The basis for this contention is, generally, that the materials and manufacturing costs of fuel cell systems will be relatively inexpensive in mass production, and that maintenance costs will be low and system longevity high because of the inherent nature of fuel cell operation.

Critical fuel cell materials consist of the platinum catalyst, the flow field plates (currently made of graphite), and the polymer electrolyte membrane. An important generic argument in favor of the potential for achieving large cost reductions is that all of the current manifestations of these components were developed for completely different applications.

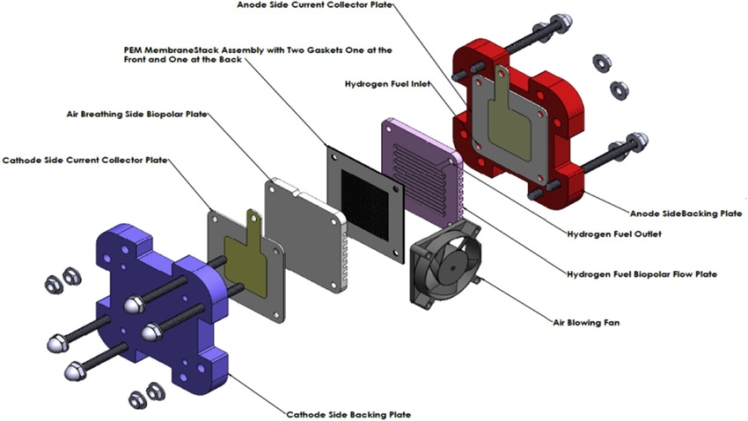

PEM Fuel Cell Details

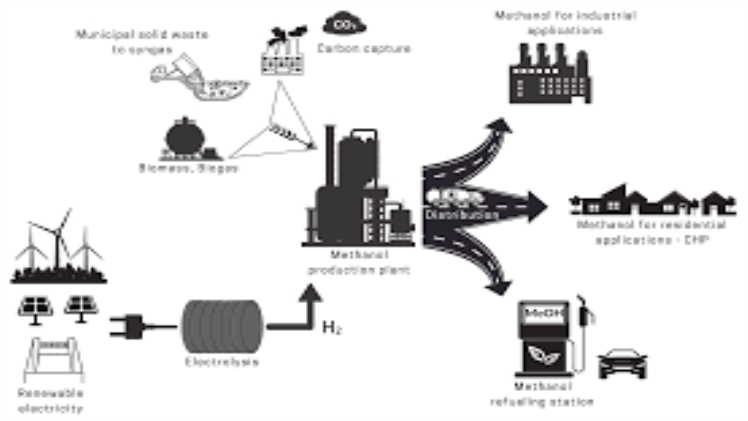

If the latter loadings can be transferred to a complete system, catalyst cost will clearly not be a problem for fuel cells. However, substantial further development and testing will be needed to establish this low a catalyst loading. In particular, for methanol based systems, a catalyst system with very light platinum loading might be very sensitive to carbon monoxide poisoning.

According to Los Alamos National Laboratory, graphite flow field plates currently cost about $270/kW and could eventually cost about $14/kW in mass production, an unacceptably high cost if fuel cell first cost is to approach internal combustion engine costs. Fuel cell developers hope to use less expensive materials, e.g., aluminum or plastics, to drastically reduce costs.

And the polymer electrolyte membranes, which now cost about $170/kW,3 are made in small quantities and may be made to higher specifications than are necessary for a fuel cell. Developers hope to utilize mass-production techniques used to manufacture other thin film materials, as well as redesign of the membrane specifications, to reduce costs by an order of magnitude or more.

Last Finishing:

Fuel cell cost projections reviewed by OTA’s contractor did not, however, contain descriptions or evaluations of fuel cell mass production procedures, and important production issues remain to be resolved, for example, sealing.5 Consequently, claims that manufacture will be at low cost, or the use by estimators of (fabrication cost)/(materials cost) ratios appear premature.

Read More About: [pii_email_e7ab94772079efbbcb25]